From concept to creation, we bring your ideas to life with cutting-edge manufacturing expertise.

At Banerjee Machines & Tools, we specifically deliver custom manufacturing solutions that prioritize quality, accuracy, and cost-effectiveness. Our modern production facility and streamlined processes allow us to serve a wide range of industries, including automotive, aerospace, consumer goods, lighting, and electronics.

With a strong commitment to innovation and customer satisfaction, we make sure that every product meets the highest standards of excellence. With advanced technology, a proficient team, and a quality-first approach, we promise outstanding products and services that improve your operational success and efficiency.

Our modern machinery and plants are equipped with the latest innovations to increase production capacity. We use advanced automation and precise engineering techniques to achieve consistent, high-quality results while minimizing lead times and maximizing cost-efficiency.

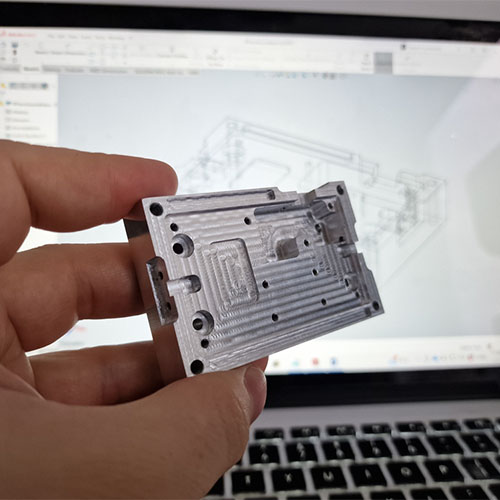

We had a team of expert designers who used modern design tools to transform concepts into reality. By understanding client requirements, we develop robust designs that form the foundation for superior manufacturing outcomes.

At Banerjee Machines & Tools Co., we emphasize quality. Our dedicated testing facility ensures that every product meets the highest industry standards. From durability evaluation to precision evaluation, our in-depth testing process ensures reliability and optimal performance.

Banerjee Machines & Tools Co. provides a wide range of high-precision engineering services tailored to meet the diverse needs of various industries. Our expertise ensures smooth manufacturing processes, improved operational efficiency, and top-notch output. Discover our main services below:

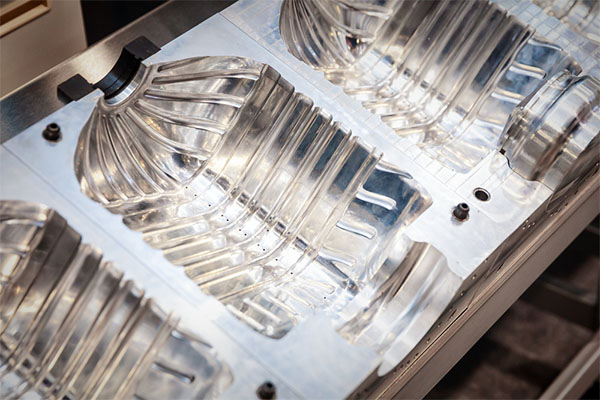

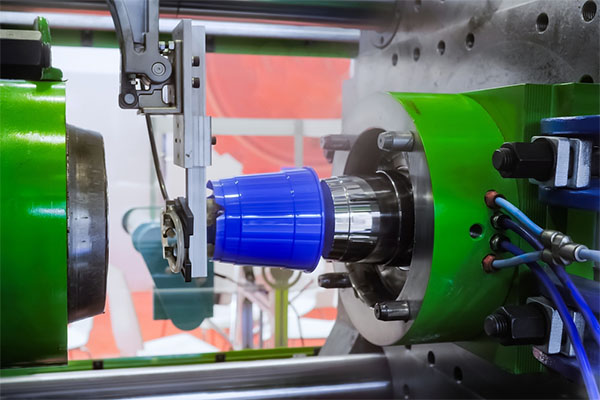

Common types include injection moulds, compression moulds, blow moulds, extrusion moulds, and rotational moulds.

Moulds are usually made from steel, aluminium, or composite materials depending on the application and durability required.

The lifespan of a mould depends on the material, usage, and maintenance. High-quality steel moulds can last for thousands to millions of cycles.

Regular cleaning, lubrication, and inspection for wear and tear help extend the mould’s lifespan and maintain product consistency.

CNC machining offers greater accuracy, repeatability, efficiency, and the ability to produce complex geometries.

Metals (steel, aluminium, titanium), plastics, composites, and ceramics can all be machined depending on the requirements.

Common types include ball valves, gate valves, globe valves, check valves, and butterfly valves.

Flow rate, pressure, temperature, material compatibility, and application type determine the best valve selection.

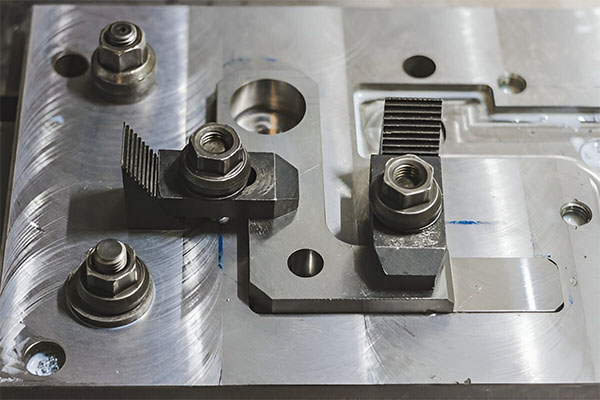

A jig is a device that holds and guides the cutting tool, ensuring accuracy and repeatability in machining operations. A fixture, on the other hand, securely holds the workpiece in place during machining but does not guide the tool.

Yes, they can be designed and manufactured to meet the specific needs of a particular part, ensuring optimal performance and precision.

2026-02-18

By Banerjee Machine & Tools Co.

This blog explores the future of Jig Manufacturing in Kolkata, highlighting key trends, technologies, and innovations led by BMT Co. to support precision, efficiency, and evolving industry demands.

Read More

2026-02-17

By Banerjee Machine & Tools Co.

This blog explains how BMT Co., a leading Industrial Valve Manufacturer in India, ensures zero-defect gate valves through strict quality control, precision manufacturing, and advanced testing processes.

Read More

2026-02-11

By Banerjee Machine & Tools Co.

Selecting the right material is crucial for the performance, durability, and precision of CNC machined parts. This blog explores key factors to consider, with expert insights from CNC Machining Service in Kolkata specialists at BMT Co.

Read More